Electric heating tube failure and solution

Electric heating tube failure and solution

Introduction of electric heating tube manufacturers, common faults and solutions of electric heating tubes, for some problems after purchasing electric heating tubes, we will sort out the following common electric heating tube faults and solutions for your reference.

Fault 1: Anti-fault wire burned

The reasons are: the heating tube burns and causes a short circuit; a lead sheet or lead wire falls off and causes a short circuit tube; the resistance wire is too small in diameter and has insufficient capacity; a short circuit caused by carbonization or dirt accumulation;

Solution: Replace the heating tube; re-welding; Replace the suitable resistance wire heating tube. Under normal circumstances, iron-chromium-aluminum resistance wire can be used. Remove dirt, repair or replace parts, repair or replace the power plug or power socket.

Fault 2: No heat

Reason: For the adjustable temperature control heating tube, the temperature controller has poor contact or melted off. The power supply is abnormal or power failure; the resistance wire has been blown; the power cord plug and the electric heating socket have poor contact, or the power cord is broken; the electric heating tube has been burned; The lead or lead of the electric heating tube is off.

Solution: The heating tube is broken and the replacement is recommended; the normal power is used; the heating tube is scrapped and reinstalled in the same type of resistance wire; check the line for repair or replacement; replace the heating to install the same size tube; re Solder lead sheets or lead.

Fault 3: Leakage

Causes: The circuit conductor falls off, the cup is in contact, the heating tube is burned, the cup is short-circuited, the grounding wire is not connected, the heating socket or plug is too dirty, the insulation of the heating tube is damaged, improper cleaning, and the cup is exposed to moisture.

Solution: Check the take-up wire and re-soldering firmly; the electric heating tube is damaged and replace the electric heating tube of the same specification; connect the grounding wire as required and check whether it is correct; clean and dry correctly; if there is such an incident, it is recommended to replace, check and repair; clean and dry correctly .

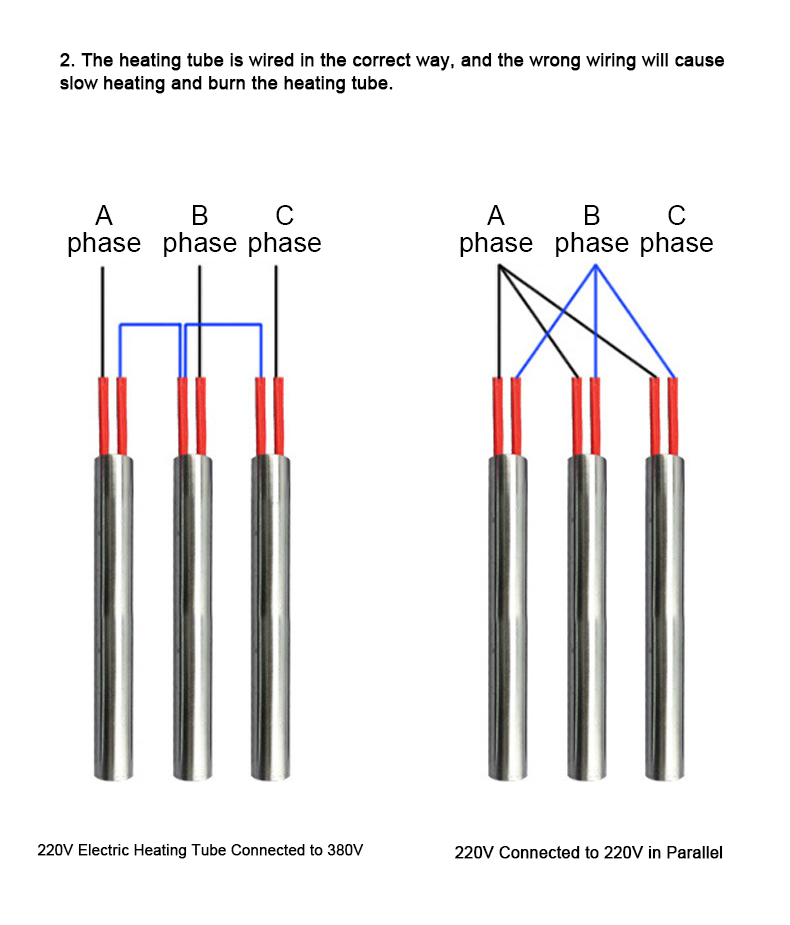

Two connection methods of heating pipe:

1. Delta connection: One end of each element is connected to the end of another element, and the three contacts are connected by three-phase wires, which does not affect the feasibility of this connection. The strength and current of the delta connection are three times that of the star connection.

2. Star connection: the heating elements of three electric heating tubes, each connected to one end (this point is called the neutral point), and the three ends are connected to the three phase wires. Features: When the rated voltage of the three elements is 220V; if the resistance of the three elements is different, the neutral point should be connected to the zero line.