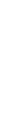

Double-headed electric heating tube is an electric heating tube with double-headed wires, with a metal tube as a protective shell (including stainless steel double-headed electric heating tube, copper tube, various imported steel materials), and spiral high-quality electric heating alloy wires are evenly distributed along the central axis of the tube ( Nickel-chromium, iron-chromium alloy heating wire), and the gap is tightly filled with crystalline magnesium oxide powder with good heat resistance, thermal conductivity and insulation. Both ends of the nozzle are sealed with silica gel and processed by other processes.

Advantage:

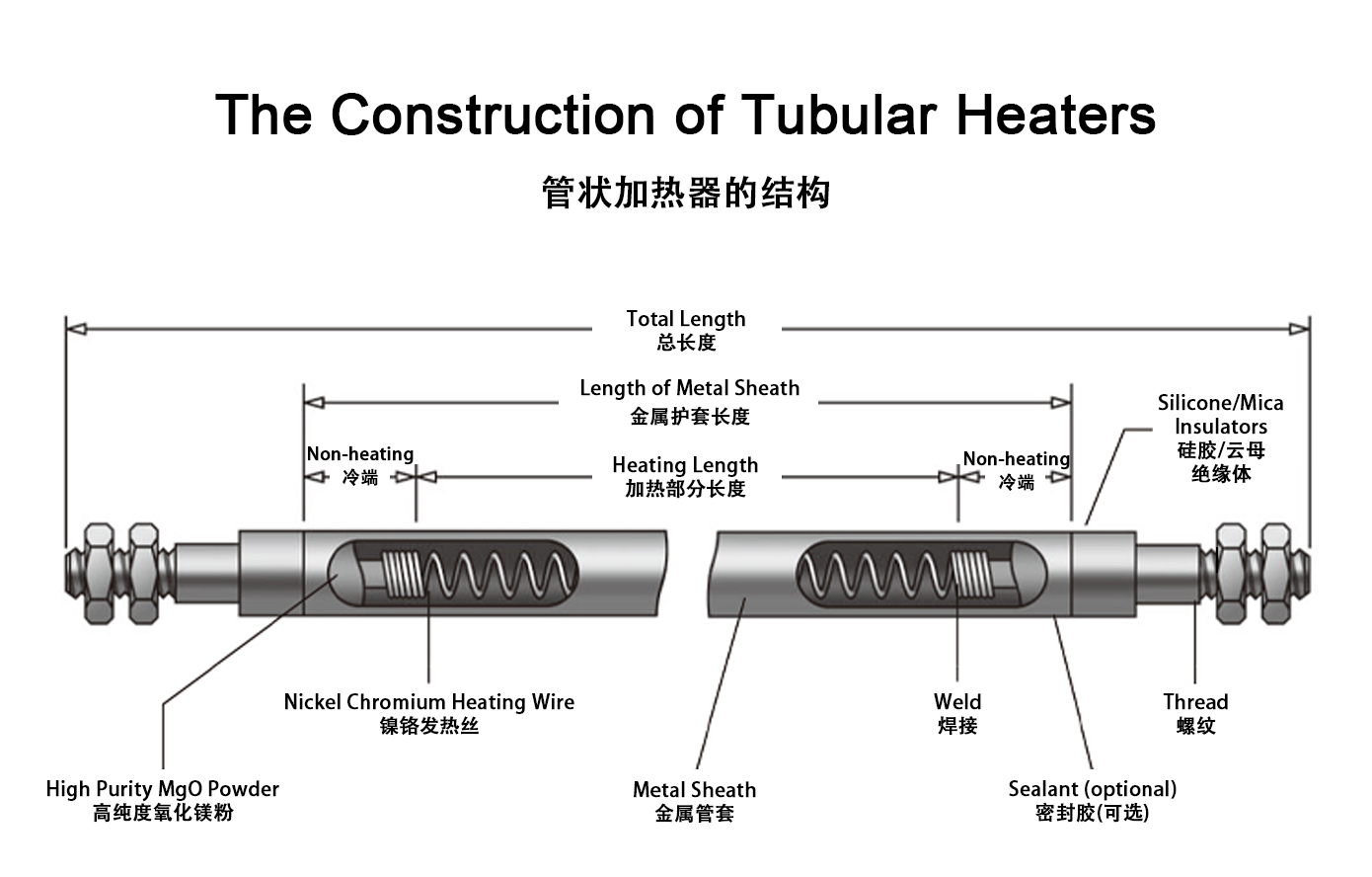

1. It can be bent almost arbitrarily, and the space and plane are utilized to the maximum extent and effectively heated;

2. It is compacted with insulated MgO, so that heat can be transferred from the resistance wire to the sheath material and medium, so as to perform effective heating faster;

3. Made of epoxy resin or silicone seals, which can resist moisture intrusion (anti-oxidation and anti-corrosion);

4. It has the characteristics of simple structure, high mechanical strength, high thermal efficiency, safety and reliability, easy installation, long service life, no pollution, and low price. It also saves electricity, is safe to use, can be bent into various shapes, is light and easy to disassemble.

Application Areas:

Radiant Heating

Oven

Dryer

Sealing Strip

Dehumidifier

Convection-air and Natural Gas

Shrink tunnel/Shrink Packaging

Mold and Manifold

Immersion Heating

Contact Heating

Chemical Industry

Straight Type: The tubular straight heater is designed to most effectively resist moisture and corrosion damage. The internal MgO insulation material is hygroscopic.

Flat Type: The tubular plate immersion heater design consists of one or more tubular elements that are brazed, welded or welded to four or six bolted flanges. The heater is directly installed on the matching flange welded to the tank wall or nozzle, maintenance and replacement are very simple, because it does not require a large amount of installation equipment, it is suitable for heating water, oil and degreasing solutions. Tubular flat heaters are commonly used in boilers and industrial storage tanks.

Hairpin Curved Type: The hairpin immersion heater is a single-curved heater with Compacted MgO insulating material.

Screw Plug Type: The tubular screw plug heater is bent into a hairpin shape, and then welded or brazed into the screw plug, depending on the compatibility of the component sheath and the screw plug of the material used. And according to the standard electrical rating system, these heaters have been tested for moisture and explosion protection.

Immersion Flange Type: Flange immersion heater is easy to install and maintain. The heater is usually used to heat liquid or gas in storage tanks and pressure vessels. The tubular part is brazed or welded to the flange part. This tube variant is very suitable for applications requiring higher kilowatts.

Note: Usually customized size and specifications/technical requirements, please refer to technical parameters for specific specifications.

Sheath Material:

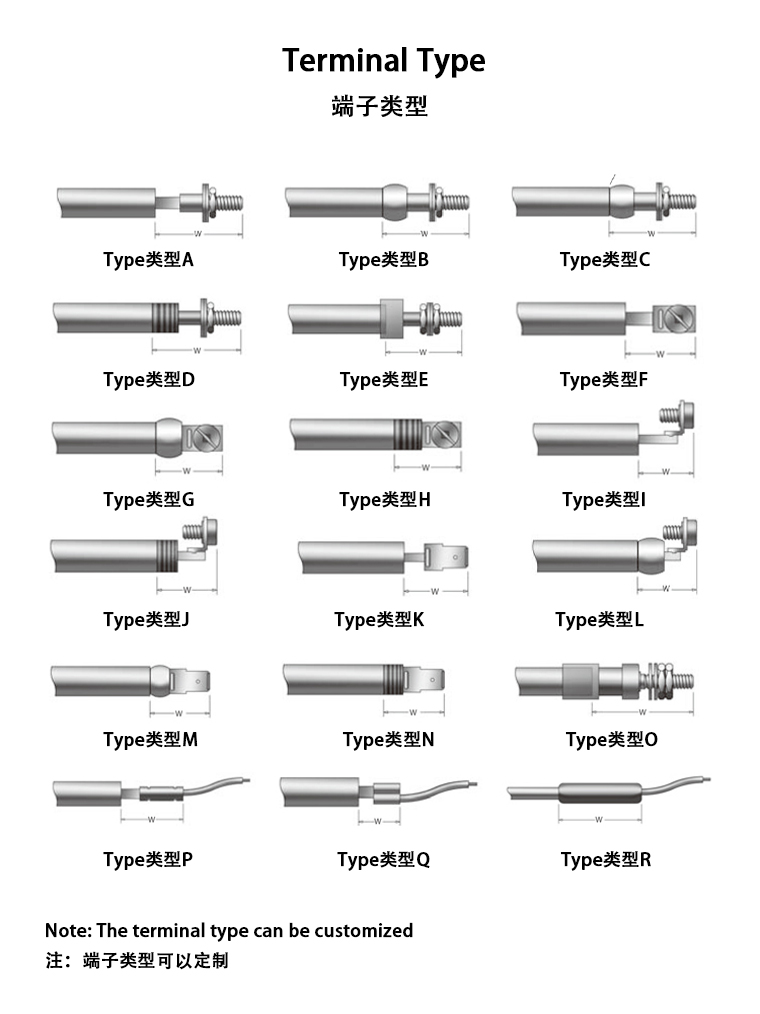

The type of sheath material of the tubular heater depends on the working temperature of the heater and the corrosiveness of the medium in the medium. The power density distribution on the surface of the tubular heater is critical for two reasons. First, it determines the temperature that the sheath of the heating element will reach under the conditions the heater is subjected to. The second reason is that each material has a specific maximum watt density, which can be tolerated during the heating cycle. The following table lists various sheath materials, the maximum allowable temperature and the recommended medium in which they are used, the recommended maximum power density and maximum operating temperature of different materials.

| Sheath Material | Sheath Max. Temperature | Application Field |

| Copper | 180℃ | Immersion in water and non-corrosive low-viscosity liquid |

| Steel | 400℃ | Oil, wax, asphalt, aluminum or iron castings |

| Stainless Steel 304-316 | 650℃ | Corrosive liquids, food industry, disinfectants |

| Nickel Cobalt Alloy | 820℃ | Air, corrosive liquid, fixed on the surface |

Density Power Tolerance:

| Solution | Maximum Watts/Square Inch | Maximum Working Temperature (℉/℃) |

| Acetic Acid | 40 | 180/82.2 |

| Chromic Acid | 40 | 180/82.2 |

| Citric Acid | 23 | 180/82.2 |

| Nitric Acid | 20-25 | 167/75 |

| Phosphoric Acid | 25-28 | 180/82.2 |

| Alkaline Solution | 40 | 212/100 |

| Asphalt, Tar | 1-40 | 200-500/93.3-260 |

| Marine Carbon Fuel Oil | 10 | 160/71.1 |

| Caustic Soda 2% | 45 | 210/98.8 |

| Caustic Soda 10% | 25 | 210/98.8 |

| Caustic Soda 75% | 10 | 180/82.2 |

| Ethylene Glycol | 30 | 300/148.8 |

| Fuel Preheating | 9 | 180/82.2 |

| Gasoline | 20 | 300/148.8 |

| Engine Oil, SAE 30 | 18 | 250/121.1 |

| Mineral Oil | 16-26 | 200-400/93.3-204.4 |

| Molasses | 4-5 | 100/37.7 |

| Thermal Oil | 12-20 | 500-650/260-343.3 |

| Vegetable Oil | 30-50 | 400/204.4 |

| Degreasing Solution | 23 | 275/135 |

| Hydraulic Oil | 12-15 | 100/37.7 |

| Sodium Phosphate | 40 | 212/100 |

| Trichloroethylene | 23 | 150/65.5 |

| Clean Water | 55-80 | 212/100 |

| Deionized Water | 60 | 212/100 |

| Softened Water | 60 | 212/100 |